High-quality heat-resistant label material

2020/8/24 16:44:16

HIT(1136)

INTRODUCTION

High temperature resistant material, commonly known as PI film in the industry, refers to polyimide film (PolyimideFilm) is the world's best performance thin film insulation material, composed of pyromellitic dianhydride (PMDA) and diaminodiphenyl ether (DDE) ) It is formed by polycondensation and casting into a film in a strong polar solvent and then imidization. It is yellow and transparent, with a relative density of 1.39~1.45. The polyimide film has excellent high and low temperature resistance, electrical insulation, and adhesion. It can be used for a long time in the temperature range of 269℃~280℃, and can reach a high temperature of 400℃ in a short time.

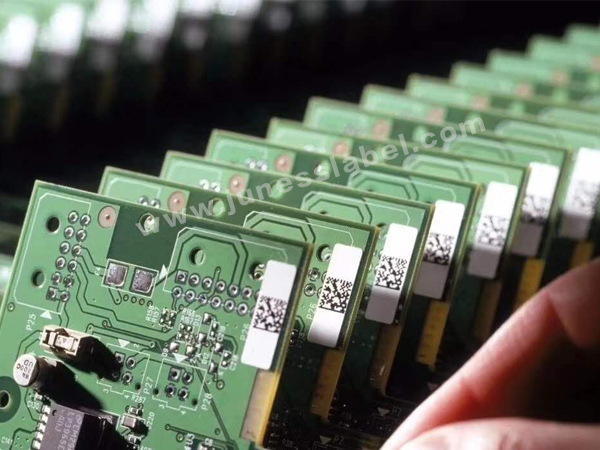

The glass transition temperatures are respectively 280°C (Upilex R), 385°C (Kapton) and above 500°C (Upilex S). The tensile strength is 200MPa at 20°C, and greater than 100MPa at 200°C. It is particularly suitable for use as a flexible printed circuit board substrate and various high-temperature resistant electrical and electronic insulation materials, or as a label material designed for identification of printed circuit boards or related electronic components. It is an ideal material that can withstand the erosion of various solders, fluxes and cleaning agents faced in the production process of circuit boards.

Suitable for thermal transfer printing technology, UV/screen printing

PI film also has a good performance in ink adhesion during the printing process

Using 1mil polyimide material

Temperature resistance: continuous 260℃-315℃ for 5 minutes, no falling off, no blistering, no deformation

Insulation: withstand voltage can reach above 8kw

At the same time, it is suitable for the board or under the PCB board processing process